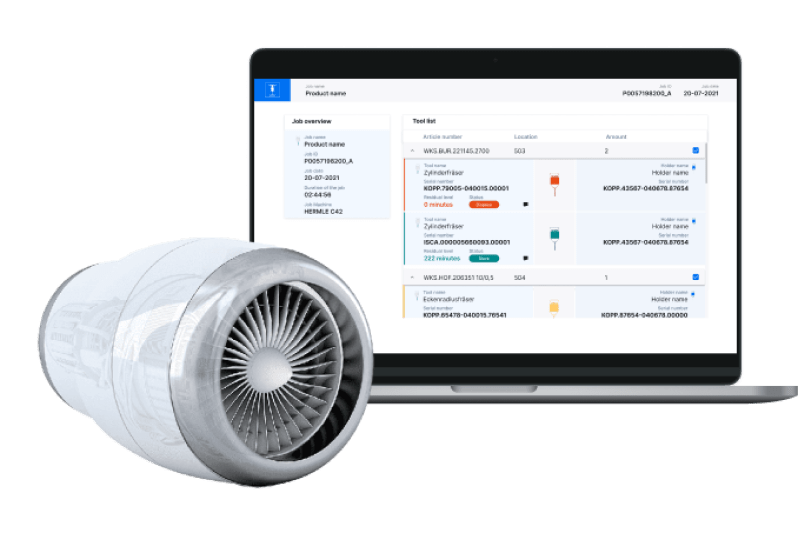

Full Lifecycle Tool Tracking Solution for Usage & Cost Optimisation

Predictive Maintenance for custom tool manufacturing in the aviation industry

For more than 25 years, AWB Anlagen, Werkzeugbau GmbH & Co KG has been producing components and tools made of the hardest and heat-resistant materials as well as special tools and individual workshop and tool containers. Since 2015, when AWB Aviation GmbH was established, we have also been a certified supplier for the aerospace industry.

Together with AWB, Technical University Darmstadt, and KOPP Co, UHP created a lifecycle tool tracking system for better tracking tool usage lifecycle for managing small tools of big factories.

Branch

Aviation industry

Technology

Angular, Angular Material, PHP

Service

Consulting, Conception, Design, Development & Support

Challenge

- Big factories with numerous small products and tools inside of machines keep track of lifecycle of each product difficultly

- Existing tool in factories can be repaired but definite amount of time and keeping track of each tools got difficult to manage for each product.

- Need for the Software that would allow for more efficient control and evaluation of their products

Solution

- Together with AWB, Technical university Darmstadt and KOPP Co, UHP created lifecycle tool tracking system for better tracking of tool usage lifecycle for managing small tools of big factory.

- The answer was creation of system that calculates the remaining useful life of tools and helps plan maintenance schedules and tool replacements

- Better overview of tools, better planning of aircraft creation, distribution of tools to partners and strengthening of partner relations.

- There will be no use of bad tools so there will be no waste of material to be used in a broken machine

Implementation

The implemented solution consists of:

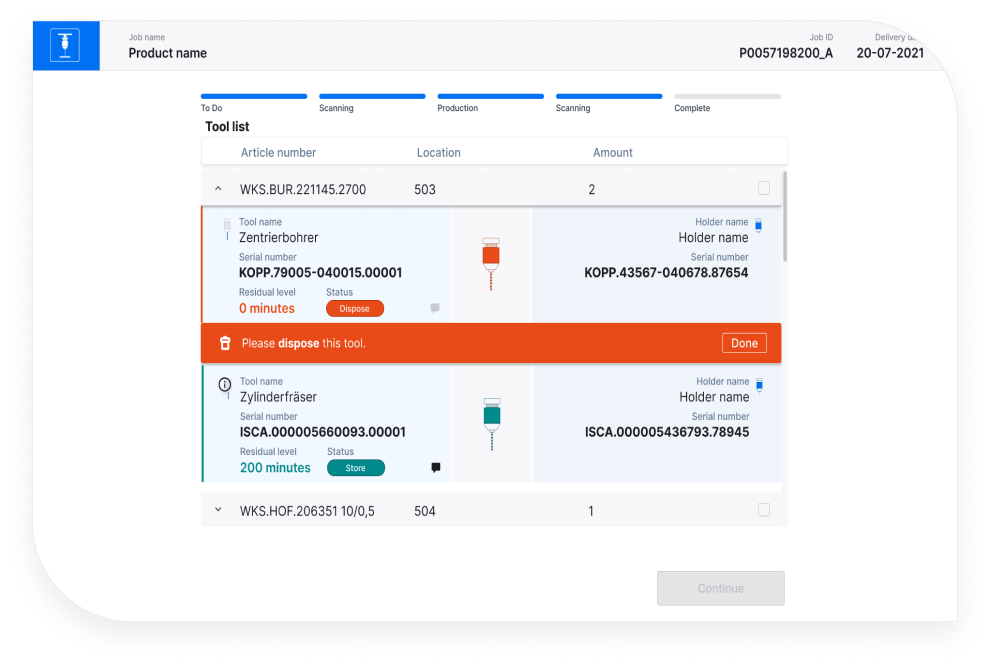

- Creation of management software for with information of each information for each tool existing in the factroy

- Creating scanning codes for each tool visible on software

- Presenting the software to workers who work with tools assembling machines and take care of the functionality and usage of machines

Deliverables

The result is better overview of tools, better planning of aircraft creation, distribution of tools to partners and strengthening the relations with existing partners. With the ENTERPRISE Software the number of hard-to-detect machine repairs is reduced as well as waste of material.

30%

Faster delivery to the clients due to better tool management

60%

Cost reduction

25%

Lower maintenance costs

Thank you for sharing your experience with us

“The UHP team's collaborative approach has made a lasting impact on us, and we are excited to keep working together, driven by the exceptional results we have achieved collectively.”

Related Stories

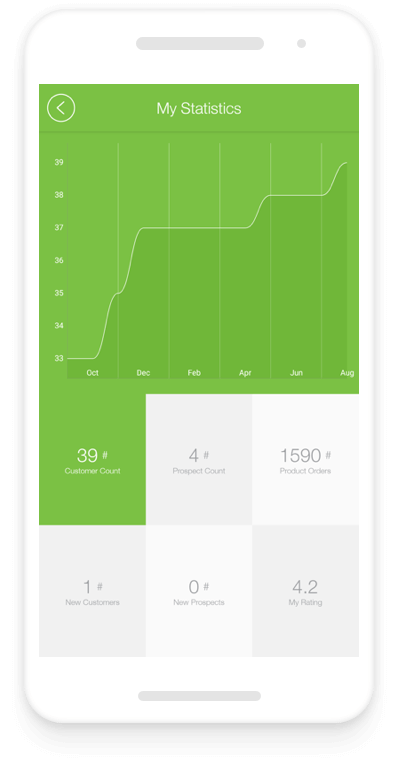

Herbalife

Android and iOS mobile apps for Herbalife members for fully digital real-time management of their customer relationships.

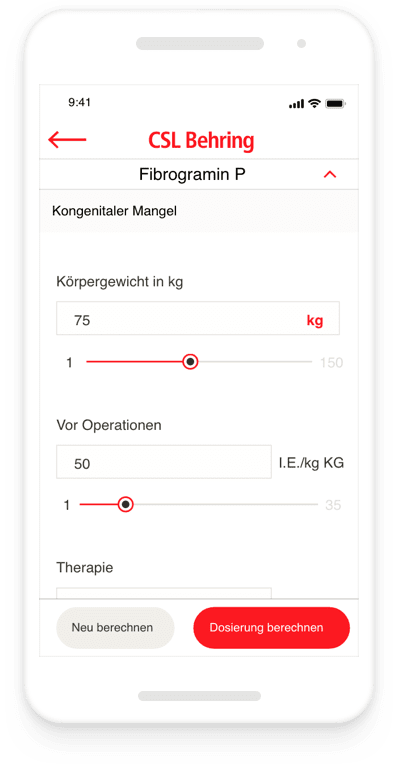

CSL Behring

A digital solution for medication calculation designed for medical professionals - certified as a Class 1 medical device.

IFM Moneo

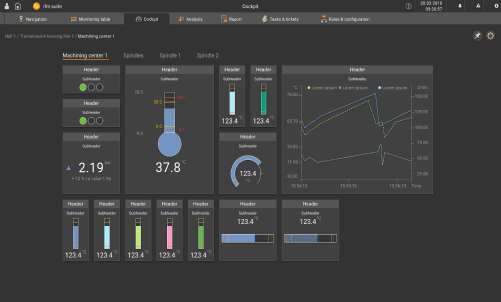

A software and service package that enables manufacturing companies to read the data from their sensors and connects them via interfaces